Cause Of Solder Balls After Reflow .mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies.

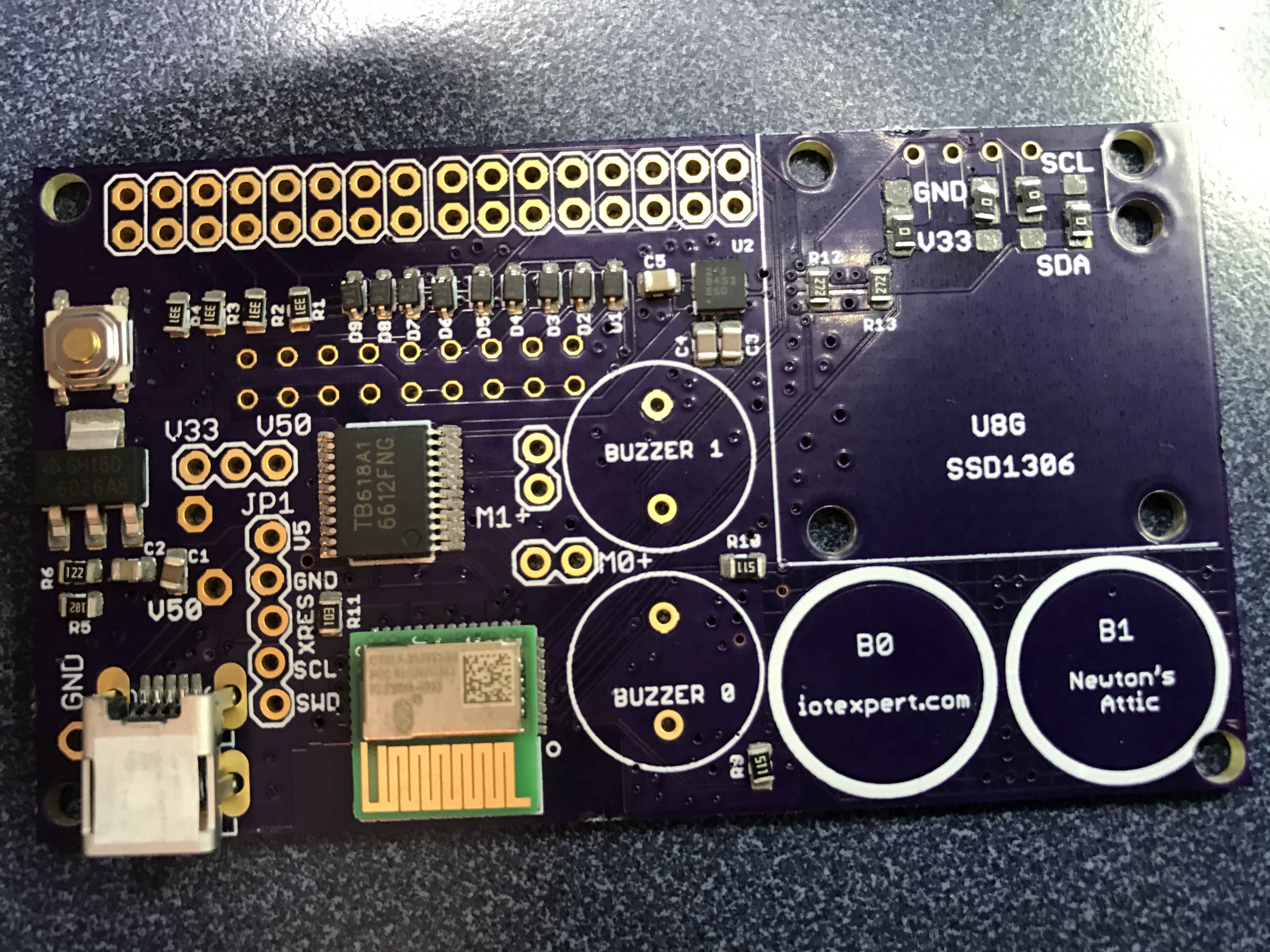

from iotexpert.com

mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. What causes solder balls during reflow. Solder balls are balls of metal alloy.

Pinball PCB Solder Reflow the OSH Park Eagle 1.2 Board IoT Expert

Cause Of Solder Balls After Reflow according to the ipc a 610 standard, a pcb is also considered defective when there are 5 solder balls (<=0.13mm) within 600mm^2.according to the ipc a 610 standard, a pcb is also considered defective when there are 5 solder balls (<=0.13mm) within 600mm^2. during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies. What causes solder balls during reflow.

From www.cambridge-sensotec.co.uk

Detecting residual oxygen within solder reflow Cambridge Sensotec Cause Of Solder Balls After Reflowaccording to the ipc a 610 standard, a pcb is also considered defective when there are 5 solder balls (<=0.13mm) within 600mm^2.mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. Too rapid heating, particularly in preheat resulting in splattering. Solder balls are balls of metal alloy. The plating. Cause Of Solder Balls After Reflow.

From www.linkedin.com

Types of Soldering Cause Of Solder Balls After Reflowmounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies.according to the ipc a 610 standard, a pcb is also considered defective when there are 5 solder balls (<=0.13mm) within 600mm^2.. Cause Of Solder Balls After Reflow.

From www.youtube.com

How to Use Solder Paste (Soldering with solder paste & heat gun) YouTube Cause Of Solder Balls After Reflow Too rapid heating, particularly in preheat resulting in splattering. Solder balls are balls of metal alloy.according to the ipc a 610 standard, a pcb is also considered defective when there are 5 solder balls (<=0.13mm) within 600mm^2. The plating layer on the surface of the pad or pin is oxidized, and the existence of the oxide layer prevents.. Cause Of Solder Balls After Reflow.

From www.s-cubed.com

Thermal Reflow Systems for Solder Balls and Pillars SCubed Cause Of Solder Balls After Reflow What causes solder balls during reflow. during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies. Too rapid heating, particularly in preheat resulting in splattering.mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. Solder balls are balls of metal alloy. Cause Of Solder Balls After Reflow.

From www.bestpcbs.com

BGS SOLDERING PCB & MCPCB Best Technology Cause Of Solder Balls After Reflowaccording to the ipc a 610 standard, a pcb is also considered defective when there are 5 solder balls (<=0.13mm) within 600mm^2. Solder balls are balls of metal alloy. during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies. The plating layer on the surface of the pad or pin is. Cause Of Solder Balls After Reflow.

From fctsolder.com

F2A reflow solder ball Solder Paste, Solder Flux FCT Solder Cause Of Solder Balls After Reflow The plating layer on the surface of the pad or pin is oxidized, and the existence of the oxide layer prevents.mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure.according to the ipc a 610 standard, a pcb is also considered defective when there are 5 solder balls. Cause Of Solder Balls After Reflow.

From siliconexposed.blogspot.com

Silicon Exposed Dummy BGAs and failure analysis Cause Of Solder Balls After Reflowmounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies. What causes solder balls during reflow. Too rapid heating, particularly in preheat resulting in splattering. Solder balls are balls of metal alloy. Cause Of Solder Balls After Reflow.

From www.semanticscholar.org

Effects of Reflow Cooling Rate on the Growth of Ag3Sn Platelets and Cause Of Solder Balls After Reflow Solder balls are balls of metal alloy. The plating layer on the surface of the pad or pin is oxidized, and the existence of the oxide layer prevents.mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure.according to the ipc a 610 standard, a pcb is also considered. Cause Of Solder Balls After Reflow.

From www.reddit.com

Soldering SMD pins; How do I avoid formation of small balls of solder Cause Of Solder Balls After Reflowaccording to the ipc a 610 standard, a pcb is also considered defective when there are 5 solder balls (<=0.13mm) within 600mm^2. Solder balls are balls of metal alloy.mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. Too rapid heating, particularly in preheat resulting in splattering. during. Cause Of Solder Balls After Reflow.

From iotexpert.com

Pinball PCB Solder Reflow the OSH Park Eagle 1.2 Board IoT Expert Cause Of Solder Balls After Reflow What causes solder balls during reflow. during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies.mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure.according to the ipc a 610 standard, a pcb is also considered defective when there are. Cause Of Solder Balls After Reflow.

From www.youtube.com

Making of a Solder Ball on a DPAK YouTube Cause Of Solder Balls After Reflowmounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. Too rapid heating, particularly in preheat resulting in splattering. What causes solder balls during reflow. during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies. The plating layer on the surface of the. Cause Of Solder Balls After Reflow.

From www.researchgate.net

(PDF) Placement and reflow of solder balls for FC, BGA, waferlevelCSP Cause Of Solder Balls After Reflow Too rapid heating, particularly in preheat resulting in splattering. Solder balls are balls of metal alloy. The plating layer on the surface of the pad or pin is oxidized, and the existence of the oxide layer prevents.mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. during reflow, solder. Cause Of Solder Balls After Reflow.

From www.researchgate.net

(PDF) Reflow influence for Sn96.7Ag3.7 polymer core solder ball in BGA Cause Of Solder Balls After Reflow The plating layer on the surface of the pad or pin is oxidized, and the existence of the oxide layer prevents.mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. Too rapid heating, particularly in preheat resulting in splattering.according to the ipc a 610 standard, a pcb is. Cause Of Solder Balls After Reflow.

From www.researchgate.net

Process system used to reflow solder balls Download Scientific Diagram Cause Of Solder Balls After Reflow The plating layer on the surface of the pad or pin is oxidized, and the existence of the oxide layer prevents. during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies. Too rapid heating, particularly in preheat resulting in splattering. What causes solder balls during reflow.according to the ipc a. Cause Of Solder Balls After Reflow.

From www.electronicsandyou.com

Basic Soldering Guide How to Solder Electronic Components Cause Of Solder Balls After Reflow Solder balls are balls of metal alloy. The plating layer on the surface of the pad or pin is oxidized, and the existence of the oxide layer prevents.mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure.according to the ipc a 610 standard, a pcb is also considered. Cause Of Solder Balls After Reflow.

From www.mdpi.com

Materials Free FullText Influence of Flux and Related Factors on Cause Of Solder Balls After Reflow Too rapid heating, particularly in preheat resulting in splattering.mounting stress is determined by some factors such as pcb thickness, component height and chip mounter nozzle pressure. during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies.according to the ipc a 610 standard, a pcb is also considered defective. Cause Of Solder Balls After Reflow.

From www.ansys.com

Solder Fatigue Causes and Prevention Ansys Cause Of Solder Balls After Reflow What causes solder balls during reflow.according to the ipc a 610 standard, a pcb is also considered defective when there are 5 solder balls (<=0.13mm) within 600mm^2. The plating layer on the surface of the pad or pin is oxidized, and the existence of the oxide layer prevents. Too rapid heating, particularly in preheat resulting in splattering. Solder. Cause Of Solder Balls After Reflow.

From de.fumaxtech.com

How to Prevent Solder balls after Reflow Cause Of Solder Balls After Reflow during reflow, solder balls could form on a pcb as solder coalesces at high temperature and solidifies. What causes solder balls during reflow.according to the ipc a 610 standard, a pcb is also considered defective when there are 5 solder balls (<=0.13mm) within 600mm^2. Too rapid heating, particularly in preheat resulting in splattering. The plating layer on. Cause Of Solder Balls After Reflow.